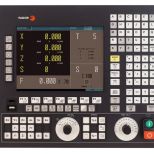

Computer numerical control CNC for lathes

FAGOR

CNC 8055 Torno

Designed for controlling high-production turning centers, vertical lathes and parallel lathes.

High speed machining

- Advanced algorithms for very accurate parts.

- Adaptive machining dynamics for best execution time.

- Work in inclined planes.

Easier machine setup

- Setup systems with graphic assistance.

- Oscilloscope function to help optimize axis behavior.

- Circularity (roundness) test that helps improve the behavior of the machine when reversing the moving direction.

Operation with the user in mind

- Operation designed for operators of conventional machines without prior programming knowledge as well as for experts on ISO-coded language.

Part preparation assistance

- Manual and automatic tool calibration.

- Part centering and part measuring cycles.

- Management of multiple part zero offsets.

- Part damage estimation.

Programming languages

- ISO-coded language for large series where optimizing the program is most important so execution time is as short as possible.

- Conversational language for small series or unitary (single) parts. It has been conceived for shops where programming time is a critical factor.

Ask for enquiry